Get ready to set sail with the exciting world of 3D printable RC boats! In this guide, we’ll dive into the ins and outs of creating your very own miniature watercraft using the power of 3D printing technology. From designing and assembling to testing and troubleshooting, we’ll cover it all, ensuring you have the knowledge to embark on a thrilling RC boat-building adventure.

Introduction to 3D Printable RC Boats

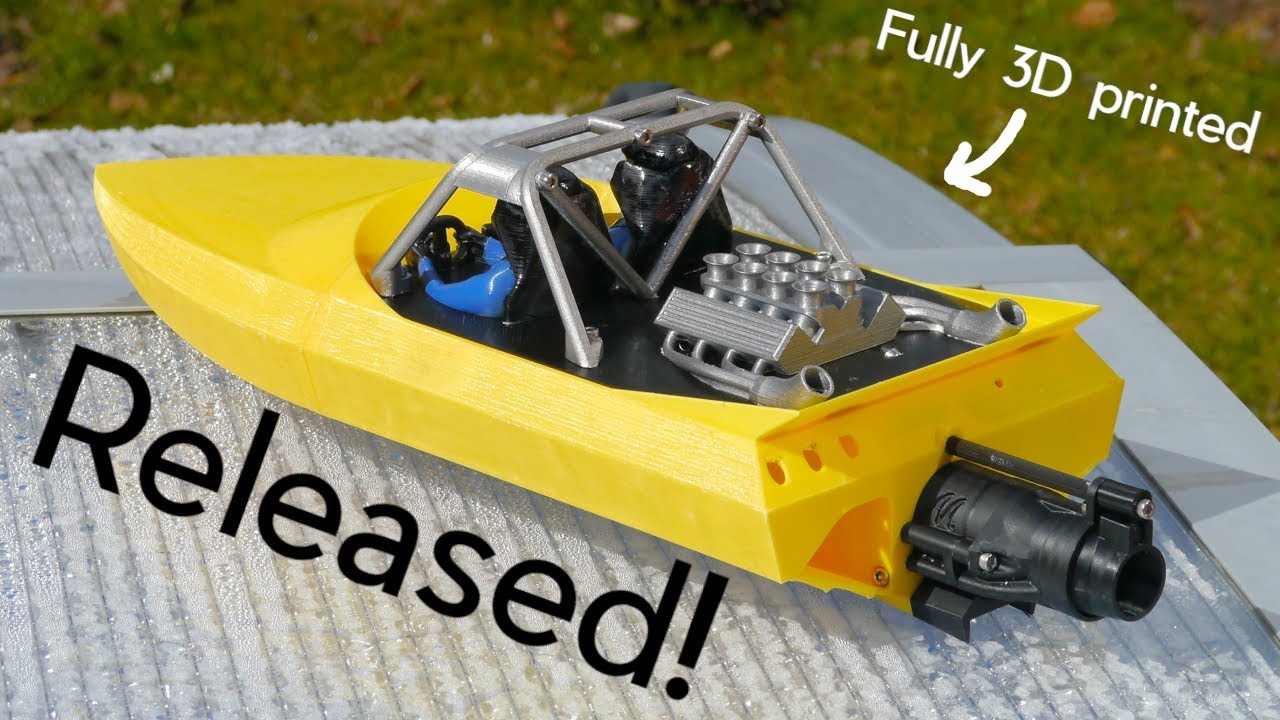

D printable RC boats are remote-controlled boats that can be created using 3D printing technology. This emerging trend combines the excitement of remote-controlled boats with the convenience and customization offered by 3D printing. These boats are typically designed using computer-aided design (CAD) software and then printed layer by layer using a 3D printer.

Significance of 3D Printable RC Boats

The introduction of 3D printable RC boats has revolutionized the RC boat hobby in several ways. Firstly, it allows enthusiasts to design and create their own unique boat models, giving them the freedom to customize every aspect of their boats.

This level of customization was not possible with traditional RC boats, which were limited to pre-designed models.Secondly, 3D printing enables the production of complex and intricate boat designs that were previously difficult or impossible to create using traditional manufacturing methods.

With 3D printing, enthusiasts can bring their imaginative boat designs to life, pushing the boundaries of what is possible in the RC boat hobby.

Advantages of 3D Printing in Creating RC Boats

There are several advantages of using 3D printing technology to create RC boats. Firstly, it allows for rapid prototyping, meaning that designers can quickly iterate and refine their boat designs before finalizing them. This saves time and resources compared to traditional manufacturing methods, where creating multiple prototypes can be costly and time-consuming.Additionally,

3D printing allows for the creation of lightweight and durable boat components. By using specialized materials such as carbon fiber-infused filaments, 3D printed boat parts can be strong and lightweight, enhancing the performance of the RC boat on the water.

Popular 3D Printable RC Boat Models

There are several popular 3D printable RC boat models that have gained recognition among enthusiasts. One example is the “RC PT Boat” model, which is a replica of the famous PT boats used during World War II. This model showcases the intricate details that can be achieved through 3D printing, capturing the essence of the historical boats.Another

popular model is the “RC Catamaran,” which features a twin-hull design that provides stability and speed. This model is often chosen by enthusiasts who enjoy high-speed racing and maneuverability on the water.

Process of 3D Printing an RC Boat

The process of 3D printing an RC boat starts with designing the boat model using CAD software. Once the design is complete, it is converted into a 3D printable file format, such as STL. This file is then loaded into a 3D printer, which prints the boat layer by layer using the chosen filament material.After

the printing process is complete, the individual boat components are assembled, and any necessary finishing touches are added. This may include sanding, painting, or applying a protective coating to enhance the appearance and durability of the boat.Overall, 3D printable RC boats provide a new level of creativity and customization in the RC boat hobby.

With the ability to design and print unique boat models, enthusiasts can truly make their mark in the world of RC boating.

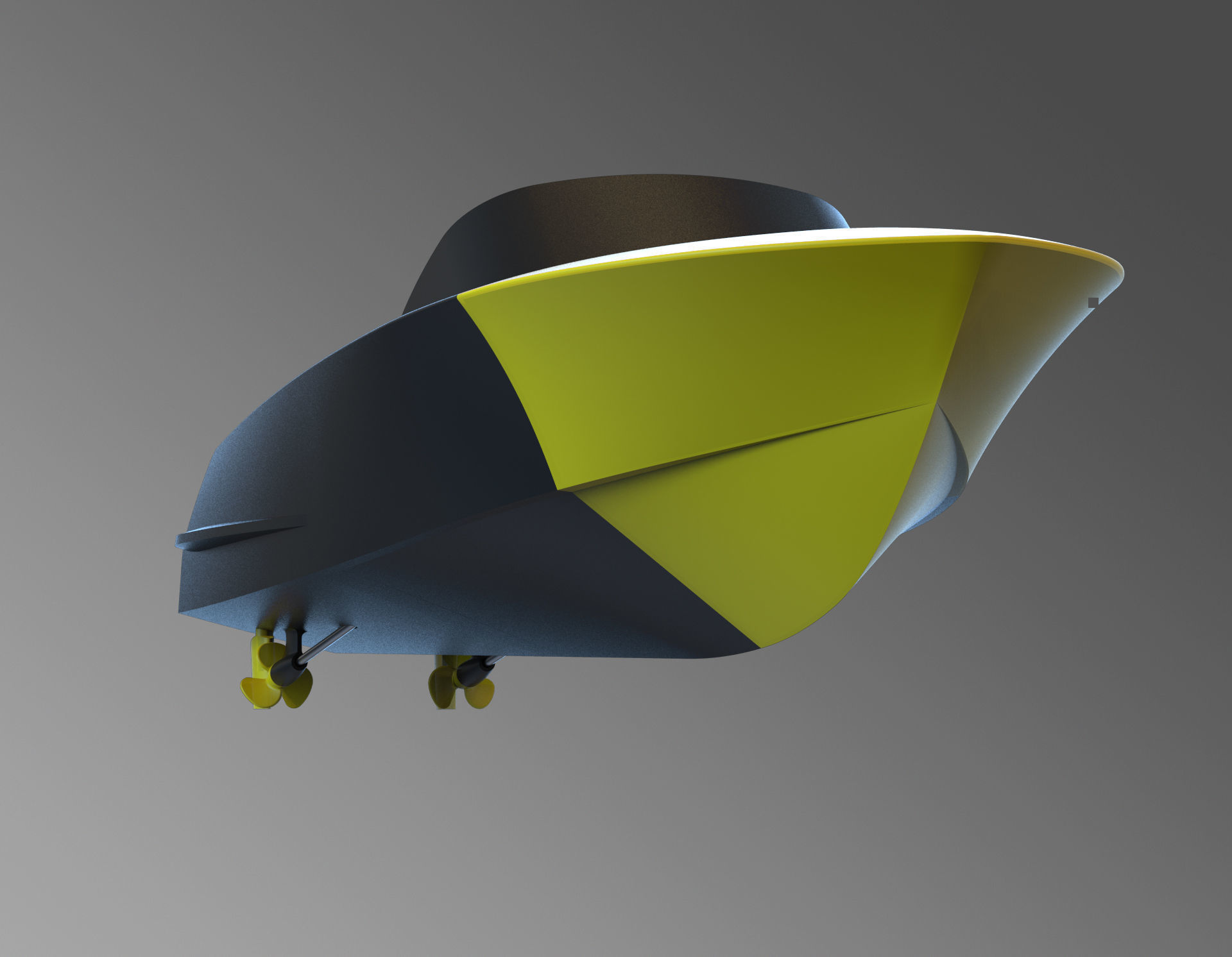

Designing a 3D Printable RC Boat

Designing a 3D printable RC boat involves several steps and considerations to ensure the final product is efficient, high-performing, and can be successfully printed using a 3D printer.

Software and Tools

To design a 3D printable RC boat, you will need specialized software and tools. Some commonly used ones include:

- Computer-Aided Design (CAD) Software: This software allows you to create the digital model of your RC boat. Popular CAD software options include AutoCAD, SolidWorks, and Fusion 360.

- 3D Modeling Software: Once you have the basic design in CAD software, you can use 3D modeling software like Blender or Rhino to add more details and refine the design.

- Slicer Software: Slicer software is used to convert the 3D model into printable layers. It helps in optimizing the printing process and generates the instructions for the 3D printer.

- 3D Printer: You will need access to a 3D printer to bring your design to life. Make sure to choose a printer suitable for the size and complexity of your RC boat design.

Tips and Techniques, 3d printable rc boat

Designing an efficient and high-performing RC boat requires attention to detail and careful consideration of various factors. Here are some tips and techniques to keep in mind:

- Hydrodynamics: Consider the shape of the hull and optimize it for minimal drag and maximum stability. Smooth curves and streamlined shapes are usually preferred for better performance.

- Weight Distribution: Proper weight distribution is crucial for balance and maneuverability. Distribute the weight evenly and position heavier components such as batteries and motors strategically to maintain stability.

- Balance: Achieving the right balance between the front and rear of the boat is important. A well-balanced RC boat will handle better in the water and have improved stability.

- Material Selection: Choose the right materials for the different parts of the boat. Consider factors such as durability, weight, and buoyancy. Reinforce critical areas that may experience higher stress.

- Testing and Iteration: It is essential to test your design in a controlled environment, such as a small pool or a calm body of water, before finalizing it. This allows you to identify any design flaws or areas for improvement and iterate accordingly.

By following these tips and techniques, you can design a 3D printable RC boat that performs well and meets your expectations.

Materials and Filaments for 3D Printing RC Boats

When it comes to 3D printing RC boats, choosing the right materials and filaments is crucial for achieving optimal performance and durability. In this section, we will discuss the different materials suitable for 3D printing RC boats, compare their properties, provide tips for material selection, and discuss the advantages and disadvantages of using different materials for various parts of the RC boat.

1. PLA (Polylactic Acid)

PLA is a popular choice for 3D printing RC boat parts due to its ease of use and affordability. It is a biodegradable thermoplastic derived from renewable resources such as cornstarch or sugarcane. PLA has good strength and stiffness, making it suitable for structural components of RC boats.

However, it is not as impact-resistant as other materials, which may limit its use for parts that are prone to high impact or stress.

2. ABS (Acrylonitrile Butadiene Styrene)

ABS is another commonly used material for 3D printing RC boat parts. It offers better impact resistance and durability compared to PLA. ABS is known for its toughness, making it suitable for parts that require flexibility and resistance to impact.

However, ABS has a higher printing temperature and can produce unpleasant fumes during printing, so proper ventilation is necessary.

3. PETG (Polyethylene Terephthalate Glycol)

PETG is a versatile material that combines the advantages of PLA and ABS. It offers good strength, durability, and impact resistance. PETG has a lower printing temperature compared to ABS and does not emit strong odors during printing. It is a good choice for RC boat parts that require both strength and flexibility.

4. Nylon

Nylon is a strong and flexible material suitable for 3D printing RC boat parts that require high impact resistance and durability. It has excellent mechanical properties, including high strength, toughness, and abrasion resistance. However, nylon can be challenging to print due to its high printing temperature and tendency to absorb moisture from the air, which may affect print quality.

5. Carbon Fiber Reinforced Filaments

For increased strength and rigidity, carbon fiber reinforced filaments can be used for 3D printing RC boat parts. These filaments contain carbon fiber strands infused into a base material such as PLA or nylon. The carbon fiber provides enhanced strength and stiffness, making it suitable for high-performance RC boat applications.

However, carbon fiber reinforced filaments can be more expensive and may require specialized settings for printing.

Tips for Material Selection

- Consider the specific requirements of your RC boat, such as the expected speed, maneuverability, and impact resistance.

- Evaluate the properties of different materials, including strength, flexibility, and durability, to determine the most suitable option for each part.

- Take into account the printing temperature and any special precautions required for each material.

- Experiment with different materials and filaments to find the best combination for your RC boat’s performance and durability needs.

Advantages and Disadvantages of Different Materials

- PLA:

- Advantages: Easy to use, affordable, biodegradable.

- Disadvantages: Limited impact resistance.

- ABS:

- Advantages: Good impact resistance, durability.

- Disadvantages: Higher printing temperature, emits fumes.

- PETG:

- Advantages: Strength, flexibility, low odor during printing.

- Disadvantages: –

- Nylon:

- Advantages: High impact resistance, toughness, abrasion resistance.

- Disadvantages: Challenging to print, moisture absorption.

- Carbon Fiber Reinforced Filaments:

- Advantages: Enhanced strength, rigidity.

- Disadvantages: Higher cost, specialized printing settings.

Assembly and Finishing of 3D Printed RC Boats

Building a 3D printed RC boat involves a step-by-step process that requires careful assembly and finishing. Proper alignment and fitting are crucial to ensure the boat functions correctly and looks aesthetically pleasing. Additionally, achieving a smooth and seamless finish on the printed parts is important for both appearance and performance.

Finally, painting and decorating the boat allows for customization and personalization.

Step-by-Step Guide on Assembling a 3D Printed RC Boat

To assemble a 3D printed RC boat, follow these steps:

- Start by organizing all the printed parts and ensuring they are free from any defects or damage. Check for any support material that needs to be removed and clean the parts thoroughly.

- Refer to the assembly instructions provided with the RC boat model. Familiarize yourself with the different components and their proper placement.

- Begin by attaching the hull pieces together. Use a strong adhesive or epoxy to securely bond the parts, ensuring they are aligned correctly.

- Next, install the motor and electronic components according to the instructions. Pay attention to proper wiring and connections to ensure the boat operates smoothly.

- Attach the propeller and rudder to the boat, ensuring they are securely fastened and aligned properly for optimal performance.

- Install the control system, such as a receiver and transmitter, following the manufacturer’s instructions. Test the controls to ensure they are functioning correctly.

- Finally, add any additional accessories or components, such as antennas, lights, or decals, to personalize your RC boat.

Importance of Proper Alignment and Fitting

Proper alignment and fitting during the assembly process are vital for the performance and aesthetics of the 3D printed RC boat. Misaligned or poorly fitted parts can affect the boat’s stability and maneuverability on the water. It can also lead to increased friction and drag, reducing the boat’s overall speed and efficiency.

Therefore, it is crucial to carefully align and fit each component to ensure optimal performance and a visually appealing final product.

Tips for a Smooth and Seamless Finish

To achieve a smooth and seamless finish on the printed parts of the RC boat, consider the following tips:

- Sand the surfaces of the printed parts using fine-grit sandpaper to remove any imperfections or rough areas.

- Apply a filler primer to fill in any remaining gaps or layer lines on the printed parts. Sand the primed surfaces again to achieve a smoother finish.

- Use multiple coats of high-quality paint, allowing each coat to dry completely before applying the next. Sand between coats for an even smoother finish.

- Consider using a clear coat or varnish to protect the paint and give the boat a glossy finish.

- Polish the painted surfaces using a polishing compound or wax to further enhance the smoothness and shine.

Options for Painting and Decorating

When it comes to painting and decorating a 3D printed RC boat, you have several options to choose from:

- Airbrushing: Airbrushing allows for precise and detailed designs. It can create gradients, shadows, and intricate patterns on the boat’s surface.

- Spray painting: Spray painting is a quick and easy option for covering large areas with a solid color. It provides a smooth finish but may not be suitable for intricate designs.

- Hand painting: Hand painting allows for more control and customization. It is ideal for adding small details or personal touches to the boat.

- Decals and stickers: Using pre-made decals or stickers is a convenient way to add logos, graphics, or other designs to your RC boat.

- Hydro dipping: Hydro dipping involves applying a printed pattern or design onto the boat’s surface using a water transfer method. It can create unique and eye-catching finishes.

Testing and Troubleshooting 3D Printed RC Boats

Testing the performance of a 3D printed RC boat is crucial to ensure its functionality and address any potential issues. By conducting thorough tests, you can evaluate the boat’s speed, maneuverability, and stability, and make necessary adjustments or modifications to enhance its performance.

The Importance of Testing

Before taking your 3D printed RC boat out on the water, it is essential to test its performance in a controlled environment. Testing allows you to identify any design flaws, weaknesses, or limitations that may affect the boat’s performance. By addressing these issues, you can prevent potential accidents or damage to the boat.

Evaluating Speed, Maneuverability, and Stability

To evaluate the speed of your 3D printed RC boat, you can measure the time it takes to travel a certain distance. This will give you an idea of its overall speed capabilities. Additionally, observing the boat’s acceleration and deceleration can help assess its performance.When

testing maneuverability, try different turning angles and observe how well the boat responds. A well-designed RC boat should be able to make sharp turns without losing control or stability. Take note of any difficulties encountered during the maneuvering process.Stability is another crucial aspect to evaluate.

Ensure that the boat maintains balance and stability while in motion. If it tends to tip over or become unstable, it may require adjustments to the weight distribution or design.

Common Issues and Troubleshooting

1. Poor Propulsion

If the boat is not moving efficiently or lacks power, check the propeller for any debris or damage. Clean or replace the propeller if necessary. Additionally, ensure that the motor is functioning properly and the batteries are fully charged.

2. Loss of Control

If you experience a loss of control over the boat, check the connection between the transmitter and receiver. Ensure that the batteries in both devices are fully charged. If the problem persists, consider adjusting the antenna position or replacing the receiver.

3. Leaks and Water Damage

Inspect the boat for any leaks or areas where water can enter. Seal any gaps or cracks with waterproof adhesive or silicone. Additionally, ensure that all electronic components are properly waterproofed to prevent damage.

4. Overheating

Do you love singing along to the classic holiday song “12 Days of Christmas”? If so, you’ll definitely want to check out the 12 days of christmas lyrics printable . This printable resource provides you with the complete lyrics to the song, making it easier to memorize and sing along.

Whether you’re planning a Christmas party or simply want to spread some holiday cheer, having the lyrics handy can make the experience even more enjoyable. So why not print out the lyrics and start practicing your singing skills? Get ready to impress your friends and family with your knowledge of this festive song!

If the motor or electronic components of the boat are overheating, it may indicate a problem with the cooling system. Check that the cooling vents are not blocked and that the water circulation is sufficient. Adjust or add additional cooling mechanisms if necessary.

Tips for Enhancing Performance

1. Weight Distribution

If you’re looking for a convenient way to plan your schedule for the next two months, you should check out the 2 month calendar printable . This printable calendar allows you to see the dates and days for two months at a glance, making it easier to organize your appointments, deadlines, and events.

Whether you need it for personal or professional use, this printable calendar is a practical tool that can help you stay organized. With its user-friendly format, you can easily customize the calendar to suit your needs. So why not give it a try and make your planning process more efficient?

Experiment with the placement of the batteries, motor, and other components to achieve optimal weight distribution. A well-balanced boat will perform better in terms of speed and stability.

2. Propeller Selection

Try different propeller sizes and designs to find the one that provides the best performance for your boat. Consider factors such as speed, acceleration, and maneuverability when selecting a propeller.

3. Adjustments to Hull Design

Depending on the type of water conditions you will be operating in, you may need to make adjustments to the hull design. For rough waters, a deeper V-shaped hull can provide better stability, while a flatter hull may be suitable for calm waters.

4. Upgrading Electronics

Consider upgrading the motor, ESC (Electronic Speed Controller), or receiver to improve the overall performance of your 3D printed RC boat. However, ensure that the upgraded components are compatible with your boat’s design and power requirements.Remember, testing and troubleshooting are ongoing processes.

Continuously monitor and evaluate the performance of your 3D printed RC boat, and make adjustments as necessary to optimize its performance on the water.

Last Recap

So there you have it – a comprehensive journey into the realm of 3D printable RC boats. With the ability to design, print, and assemble your own miniature watercraft, the possibilities are endless. Whether you’re a seasoned RC boat enthusiast or a newcomer to the hobby, the world of 3D printing opens up a whole new world of creativity and excitement.

So grab your virtual captain’s hat and get ready to navigate the waters of RC boat-building like never before!

Answers to Common Questions

Can I really build my own RC boat using 3D printing?

Absolutely! 3D printing technology allows you to bring your design ideas to life and create customized RC boats from scratch. With the right tools and materials, you can build a high-performing watercraft that’s uniquely yours.

What are the advantages of 3D printing for RC boats?

3D printing offers numerous benefits for RC boat enthusiasts. It allows for intricate and complex designs, offers flexibility in material choices, and enables rapid prototyping. Additionally, it provides the opportunity for customization and modification to enhance performance.

Which materials are suitable for 3D printing RC boats?

There are various materials and filaments suitable for 3D printing RC boats, such as PLA, ABS, and PETG. Each material has its own properties and considerations, so it’s important to select the one that best suits your specific requirements, taking into account factors like durability and buoyancy.

How do I assemble a 3D printed RC boat?

Assembling a 3D printed RC boat involves following a step-by-step process, including aligning and fitting the parts properly. It’s crucial to ensure everything is securely connected and functioning correctly. Refer to our comprehensive guide for detailed instructions on assembling your own RC boat.

What should I do if my 3D printed RC boat encounters performance issues?

If you experience performance issues with your 3D printed RC boat, don’t worry! We’ve got you covered. Our troubleshooting tips will help you identify common issues and provide solutions to enhance the speed, maneuverability, and stability of your watercraft.